Project Description

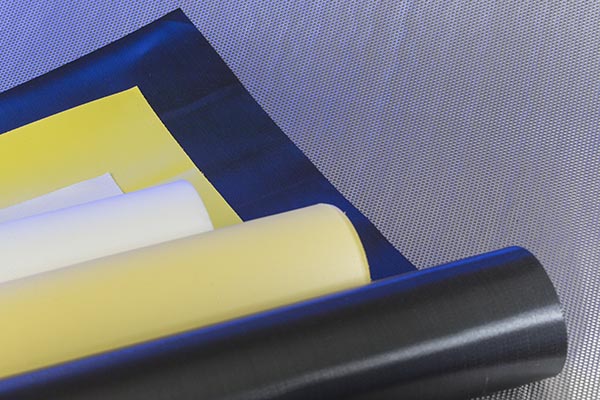

Filter Cloths

Depending on the task, ViRA Sanat Adonis offers different filter plates and cloths, meeting the individual requirements from specific customers.

Brief

As a longstanding supplier of filter press systems, ViRA knows exactly which filter cloths delivers the best results. ViRA offers the full range of filter cloths in all variants – whether for ViRA filter presses or for third-party systems.

ViRA has great experience and offers competent and fair advice for selecting the correct filter cloth.

ViRA also offers filter cloths manufactured to customer drawings of the cloth or plate as well as to sample cloths supplied (used, but dry and cleaned, so the most important parameters for manufacturing can be identified).

Description

General information

The fabric for the filter cloths are cut to size accurately with laser technology.

ViRA filter cloths are available in all variants: as barrel-neck cloths, overhang cloths or with sealing edge.

Barrel-neck cloths consist of two fabric layers which are connected to a sewn-on fabric neck.

For the overhang cloths, the fabric is placed over the filter plate so both sides are covered. Today, overhang cloths are usually only used as rough underlay cloths for barrel-neck cloths to serve as drainage. For modern filter plates with appropriate support for the outflow, underlay cloths have basically become superfluous.

There is a customer base, however, who still need underlay cloths, so ViRA continues to offer these.

For special “non-drip” filter plates, filter cloths are available with a sewn-in sealing edge which fits precisely into a groove in the filter plate. The filter chamber itself has an additional sealing ring on the edge to provide sealing to the outside. This sealing ensures that no emissions occur during operation of the filter press. This allows compliance with special environmental and health and safety regulations for critical suspensions.

Materials

Polypropylene filter cloths are most commonly used for filter presses. But a large number of other materials is also available, e.g. if certain chemicals or high temperatures exclude the use of polypropylene:

– Polyamide for certain solvents and for constant temperatures between 90 °C and 110 °C.

– Polyester, e.g. for certain chemical filtrates at temperatures up to 170 °C.

Fabric

The filter action is a result of the mesh size and the type of filament. The filter cloths are woven with particular precision and evenness so the mesh has its own stability and keeps its structure even under application conditions. This prevents premature blocking or partially different draining of the filter cake.

Monofilaments are used to minimize adhesion of the filter cake on the filter cloth. These fabrics do not wrinkle because they are relaxed on rollers at high temperatures, so-called thermosetting.

If the particles are much smaller than the mesh size, filtration can only be achieved with multifilaments. No mesh openings are visible and the suspension has to flow through the fiber filter matrix, where the very fine particles are filtered. Multifilament cloths have a rough surface, though, and therefore the filter cake can adhere better. Calendered multifilament cloths are an improvement. The fine fibers are lowered, as with ironing, to reduce adhesion.

The combination of a fabric with mixed filaments is the optimum solution here for filtering smallest particles with multifilaments while still achieving low adhesion of the filter cake.

Variant options

Seams

The intake hole with the cloth neck can be centered or in the middle for filter plates. ViRA offers the right filter cloths for all plate types.

The cloth neck has to have sturdy seams to offer support against abrasive suspensions. Good quality really becomes evident during cleaning with a pressure washer. The single seam on ViRA filter cloths already has a high quality as a standard and is superior to many competitors products.

Felt edge

To increase sealing at the edges and to protect the cloth for plates with tappets, an optional felt strip can be sewn on.

Result

Various Materials

Variety in Weave

Proper Offer

Technical Data

| Item | Data |

|---|---|

| Material | Polypropylene |

| Cloth neck material | Polypropylene |

| Air permeability | 3 – 1500 l/min dm² at 20 mm |

| Max. operating temperature | 70 – 95 °C for water-based applications |

| Application examples | Wastewater systems in electroplating and chemical industry, purification plants |

Ready to Talk?

DO YOU HAVE A BIG IDEA WE CAN HELP WITH?

Email:

info@virasanatadonis.com

virasanatadonis@gmail.com

Phone:

+98 26 4425 3106

+989124092334